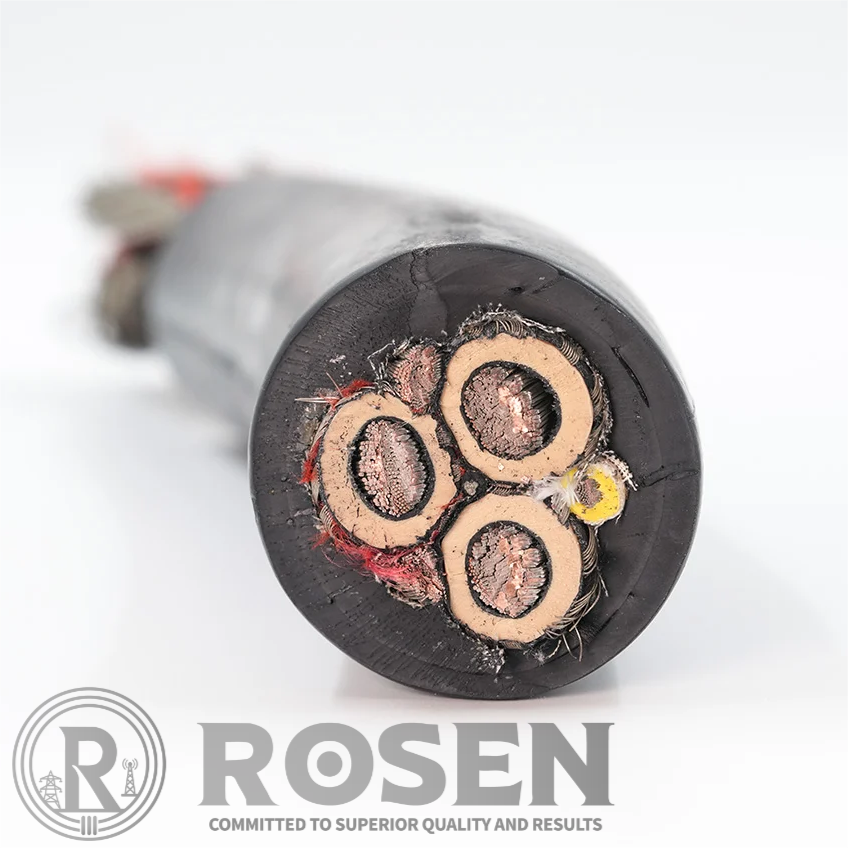

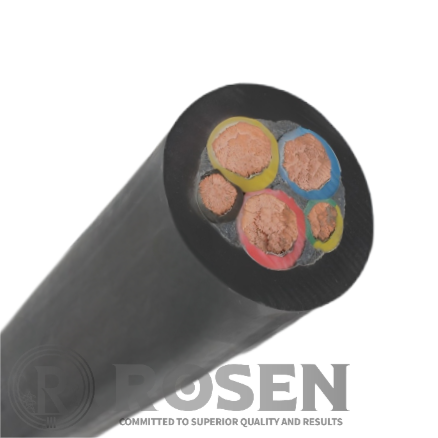

1.Conductor:

Tin coated, soft drawn, annealed, flexible, rope-lay stranded copper per ASTM B33/B172

2.Separator Tape:

Semi-conducting tape applied between the conductor and insulation to facilitate stripping

3.Conductor Shield:

Semi-conducting cross-linked copolymer

4.Insulation:

Ethylene Propylene Rubber (EPR) 100% Insulation Level

5.Insulation Shield:

Semi-conducting cross-linked copolymer

6.Shield Separator:

Semi-conducting SBR tape applied to the phase insulation with a 50% overlap, adhesive side up

7.Braid Shield:

Tin coated, soft drawn, annealed, copper braid shield (60% minimum coverage), combined with color coded nylon (black, white, red) with a 40% maximum coverage

8.Ground Check Conductor:

Tin coated, soft drawn, annealed, rope stranded, flexible lay copper per ASTM B33/B172 with yellow, high strength, polypropylene insulation

9.Ground Conductors:

Two uninsulated, tin coated, soft drawn, annealed, rope stranded, flexible lay copper per ASTM B33/B172

10.Tape:

SBR tape applied over the cabled core for improved mechanical integrity and ease of stripping

11.Inner Jacket:

Black, mold cured, extra heavy-duty modified integral fill flame resistant, thermosetting Chlorinated Polyethylene

12.Reinforcement:

Reinforcing twine applied between the two jacket layers

13.Outer Jacket:

Black, mold cured, extra heavy-duty, flame resistant, thermosetting Chlorinated Polyethylene (CPE). Other colors available

14.Reflective Stripe:

Highly visible reflective stripe embedded into the outer jacket to increase safety and help prevent cable runover (optional, contact your sales representative for part number)